Recent amendments to New Zealand’s Employment Relations Act introduced detailed requirements with regards to meal and rest breaks for transportation employees.

Scheduling for fixed-route services – and especially the creation of optimized crew schedules – requires compliance with meal and rest break rules. This is no trivial feat: vehicle and crew scheduling is a complex problem called NP-hard in computer science, and it requires the use of advanced algorithms to build optimal schedules, which can create significant operational savings and better shifts for operators. Some of the software that creates these scenarios takes hours to run one optimization, making compliance complex, or requiring extensive changes to the software.

In fact, adding meal and rest breaks can run the risk of “breaking” historical schedules, resulting in two choices: non-compliance with the law since the crew schedule won’t provide the required breaks, or a schedule which requires too many drivers or has other issues, such as too many split shifts.

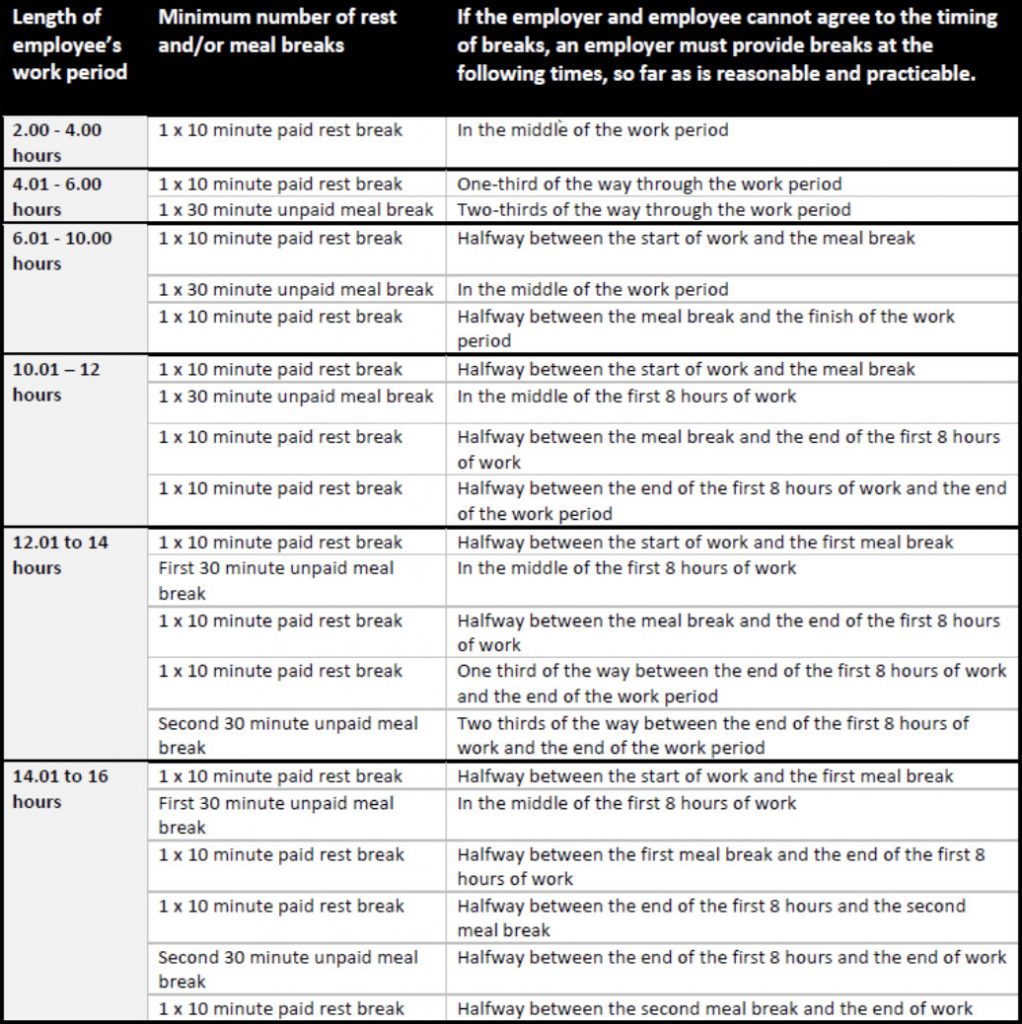

One of the unique challenges associated with the ERA break rules was that they are highly specific with regards to the timing and length of the breaks (at least in case there is no other agreement in place between the employer and employees), as you can see below:

As you can see above, the rules indicate both the length and the timing of the break at a high degree of specificity. Timing in this can is complex, since the breaks are taken relatively to the length of the shift or the last break, as opposed to a simpler statement such as “every three hours”.

Let’s look at what implementing the ERA would do to a given (theoretical) schedule, and then see how we can implement a series of iterations to arrive at a schedule that is both optimized and complies with the ERA. This is important in the context of negotiating with the union, since potential variations on the ERA can be quickly modelled, so that both parties can discover a win-win variation on the ERA that would service efficiency and driver comfort.

Originally, the schedule is not compliant with the ERA, and requires 120 duties. Extensive manual-only scheduling created a 135 duty schedule, but about 25% of the duties were in violation of the ERA. Our goal is to see whether software can do a better job…

Let’s see what compliance with the ERA will bring. This will be accomplished by a series of steps, as follows:

- First Variation: Fully enforced ERA on existing schedule

First, we took the existing schedule and defined break preferences that create a full enforcement of the ERA rules, including the number, order and pattern of breaks.

Here is the breakdown of the core KPIs:

It’s pretty clear that the schedule won’t do, since the number of duties is very high – 162 – and many of them are split shifts, which also poses a problem.Cost 100% Duties 162 Blocks 92 Crew efficiency 73% Split Shifts 44 - Second variation: constraining duty numbers and types

At this point, we added constraints, mainly to bring back the number of duties to within the range of the current number of drivers. We also imposed limitations on the number of types of duties, to create a better quality result. With a 10% increase in split shifts, we managed to reduce the duty count and lower costs:Here is the breakdown of the core KPIs:

Cost 95% Duties 141 Blocks 91 Crew efficiency 74% Split Shifts 44

Yet, in this case the duty number was still high. - Third variation: relaxing the timing requirements, limiting duties and number of split shifts

Let’s check the impact of a more lenient ERA implementation (which can be achieved through an agreement with drivers), complying with the requirement for the number and order of breaks, but relaxing the requirement with regards to the exact timing of the break. For instance, 4-6 hour work periods require a rest break one-third of the way through the work period and a meal break two-thirds of the way through the work period. We will only enforce the number of breaks (1 rest, 1 meal) and the order (rest before meal) while the timing within the duty ( one-third of the way through the work period) is not enforced. We also limited the amount of duties and split shifts.Here is the breakdown of the core KPIs:

Cost 93% Duties 135 Blocks 92 Crew efficiency 78% Split Shifts 40

This was the option that was chosen, to fully implement the ERA whilst being certain that the schedule is compliant and valid.

Conclusion

Next-generation scheduling and planning platform apply algorithms together with an easy to use interface to quickly deliver responses to scheduling and compliance needs, balancing compliance and employee well being with the financial and operational efficiency that is required.